Actually this title came to my mind from my first company where I joined as a graduate engineer trainee in 2016 now I am going to share with you how the bars take a shape of blank gears.

Stage -1

Raw material selection

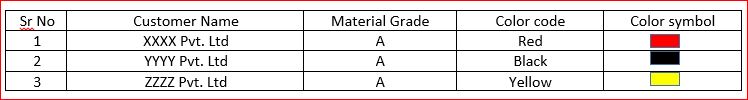

As per customer requirement we procure the suggested material for manufacturing and after material delivery we cut a slice of bar and send to the metallurgical testing department where we cross verify the material specification is ok or, not as per our requirement if material pass this test then we put our internal color code on the bars. Color code is essential to control grade mixing if we will not put internal color code on the bars then it is difficult to identify the material grade because of in raw material storage section have multiple grades for multiple customers and we have also same grade of material for multiple customer so we make a color code chart in which customer name and their grades color are mentioned and we put color code on the bars according to it.

Color code chart

Stage -2

Billets cutting

In this stage we decide the weight of billet from part model to keep some few consideration to fill the part and provide the billet weight to raw material cutting section and they start the billet cutting via shearing machine and band saw but mostly we use the shearing machine because of it takes minimum time to cutting.

Stage -3

Forging section

After billet cutting we again put color code on it and send it in forging section to shape it. Before shaping we put the billets into the heater to acquire specific temp it depends on material grade but generally we use 900 degree to 1000 degree temp and after that we put the billet into die and hammer fall down and billet get a shape.

Stage -4

Heat treatment section

After shaping process we send the forged material for heat treatment process where, as per customer requirement we do the process like normalizing, quenching, nitriding etc.

Stage -5

Shot blasting

In this process we remove the scale and surface contaminants by steel ball.

Stage -6

Pre machining

In this process we remove the flash by using of lathe machine.

Stage -7

Final CNC machining

In this process we make a final shape and required dimension, required surface finish and after that it goes to inspection department where we insure the part is ok for final teeth cutting and before dispatch we do crack testing and grade testing.

Leave a comment